Casting number 10239906, the heavier duty ones with the harder, pressed-in exhaust valve seats.

Dont believe the hype that these Vortecs are not as good at the 062's. That was a myth that has been disproven many times on the dyno.

I will be around. Please give me a heads-up, as I am working long days right now.

Thinking about a new Cam

- mattawajeep

- Posts: 1221

- Joined: Wed May 19, 2010 6:18 pm

- Location: Mattawa, WA

- mattawajeep

- Posts: 1221

- Joined: Wed May 19, 2010 6:18 pm

- Location: Mattawa, WA

So, good news and bad news.

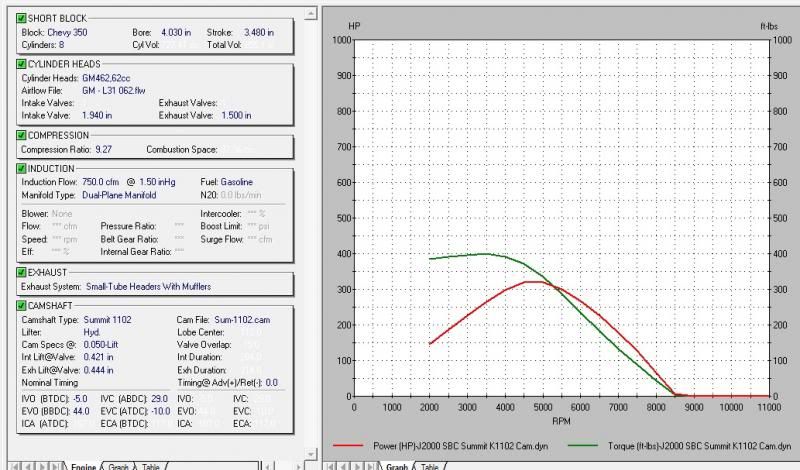

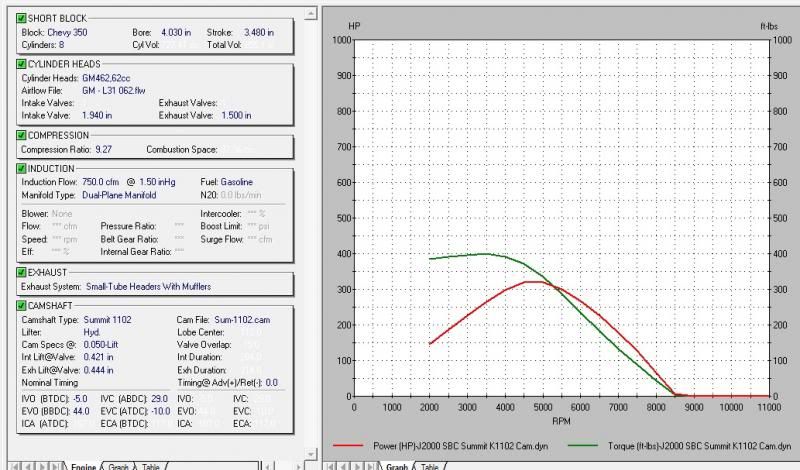

Good news is that the aftermarket fastburns are pretty darn close to the stock vortec heads. Looked up some info and you're right, 906's and 602's are pretty much the same. Put in some new numbers and came up with this.

Now, the bad news. I've pulled off one main bearing cap so far, and this is what I've found:

Yuck

Oh well, clearances aren't terrible so I suppose that's helpful in figuring out what bearings to get.

So, what would you guys do here? Check out all the bearings, record the size and clearance, then order a new set, individuals? Any opinions on what clearances I should be looking for for my application? Opinions on bearing type and brand? They seem to run from pretty cheap to super expensive.

Good news is that the aftermarket fastburns are pretty darn close to the stock vortec heads. Looked up some info and you're right, 906's and 602's are pretty much the same. Put in some new numbers and came up with this.

Now, the bad news. I've pulled off one main bearing cap so far, and this is what I've found:

Yuck

Oh well, clearances aren't terrible so I suppose that's helpful in figuring out what bearings to get.

So, what would you guys do here? Check out all the bearings, record the size and clearance, then order a new set, individuals? Any opinions on what clearances I should be looking for for my application? Opinions on bearing type and brand? They seem to run from pretty cheap to super expensive.

- White trash

- Posts: 1763

- Joined: Tue Jan 22, 2008 9:38 pm

- Location: El Pasco

That bearing doesn't look all that bad. Not awesome but certainly not terminal either.

If I was in your shoes I'd pull all the rods and mains and if none of them are way out of spec on the plastigage just slap another set of clevite bearings in there and run it. If you have a particularly bad journal having the crank polished would be a good idea.

On another note the tbi stuff is in a tote along with the a/c parts, brackets etc. There is some extra gm parts in there too, if you can't use it you won't hurt my feelings by chucking it.

If I was in your shoes I'd pull all the rods and mains and if none of them are way out of spec on the plastigage just slap another set of clevite bearings in there and run it. If you have a particularly bad journal having the crank polished would be a good idea.

On another note the tbi stuff is in a tote along with the a/c parts, brackets etc. There is some extra gm parts in there too, if you can't use it you won't hurt my feelings by chucking it.

- mattawajeep

- Posts: 1221

- Joined: Wed May 19, 2010 6:18 pm

- Location: Mattawa, WA

White trash wrote:That bearing doesn't look all that bad. Not awesome but certainly not terminal either.

If I was in your shoes I'd pull all the rods and mains and if none of them are way out of spec on the plastigage just slap another set of clevite bearings in there and run it. If you have a particularly bad journal having the crank polished would be a good idea.

On another note the tbi stuff is in a tote along with the a/c parts, brackets etc. There is some extra gm parts in there too, if you can't use it you won't hurt my feelings by chucking it.

Yeah, guess that's what I'm going to have to do. Tearing stuff apart is dangerous. Makes me want to button this thing all back up, ensure it runs, sell it, and look for cheap short blocks.

Can you pull out the crank with the pistons still in the block? Think I might move this engine to an unused shop in the orchard, or down in the basement, too much dust in the garage to be going this deep.

If you're not around when I make it in to town I'll just leave the money in an envelope or something.

- White trash

- Posts: 1763

- Joined: Tue Jan 22, 2008 9:38 pm

- Location: El Pasco

Yes you can pull the crank with the pistons in place. Just mark the rod caps as to where they go (I use a punch to peen the number of hole into the machined surface of the cap) and put some fuel line on the rod bolts to protect the journals. It is helpful to knock the pistons to the top of their bores as you pull the caps so you have room to move the crank.

From the sounds of it I'll be back home in the mid afternoon tuesday so it shouldn't be a problem.

From the sounds of it I'll be back home in the mid afternoon tuesday so it shouldn't be a problem.

- mattawajeep

- Posts: 1221

- Joined: Wed May 19, 2010 6:18 pm

- Location: Mattawa, WA

Got all the main bearings checked, but I ran out of plastigage. I'll have to do the rods tomorrow.

#1

Has a couple nicks in the bearing surface. .002 Clearance

#2

Some wear - .002 clearance

#3

Some wear - .003 clearance

#4

Lots of wear - between .002 and .003 clearance

#5

Some wear, not as much as others - pretty close to .002 clearance

#1

Has a couple nicks in the bearing surface. .002 Clearance

#2

Some wear - .002 clearance

#3

Some wear - .003 clearance

#4

Lots of wear - between .002 and .003 clearance

#5

Some wear, not as much as others - pretty close to .002 clearance

- mattawajeep

- Posts: 1221

- Joined: Wed May 19, 2010 6:18 pm

- Location: Mattawa, WA

So, I got springs figured out for the Vortec heads. Ordered a set that will drop in with no machine work, comes with retainers, locks, shims, and new seals.

Now I just need to get them installed. I'm trying to be cheap here, anyone have the tools to do the job that I could borrow/rent/lease? Or do you think I should just bite the bullet and pay a machine shop to set them up for me? I'd like to set them at 100lbs seat pressure, but have absolutely none of the required tools.

Now I just need to get them installed. I'm trying to be cheap here, anyone have the tools to do the job that I could borrow/rent/lease? Or do you think I should just bite the bullet and pay a machine shop to set them up for me? I'd like to set them at 100lbs seat pressure, but have absolutely none of the required tools.

- mattawajeep

- Posts: 1221

- Joined: Wed May 19, 2010 6:18 pm

- Location: Mattawa, WA

Return to “Projects and Build-Ups”

Who is online

Users browsing this forum: No registered users and 85 guests