Gas lens kit for my tig torch came in last week, been dying to try it on something.

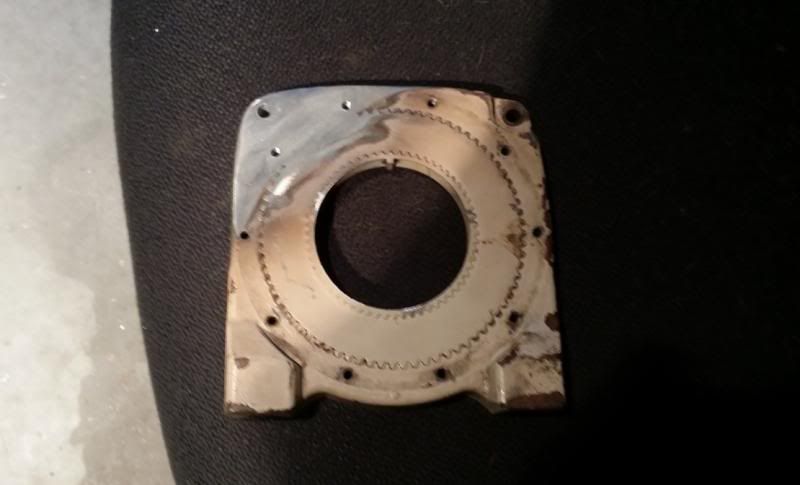

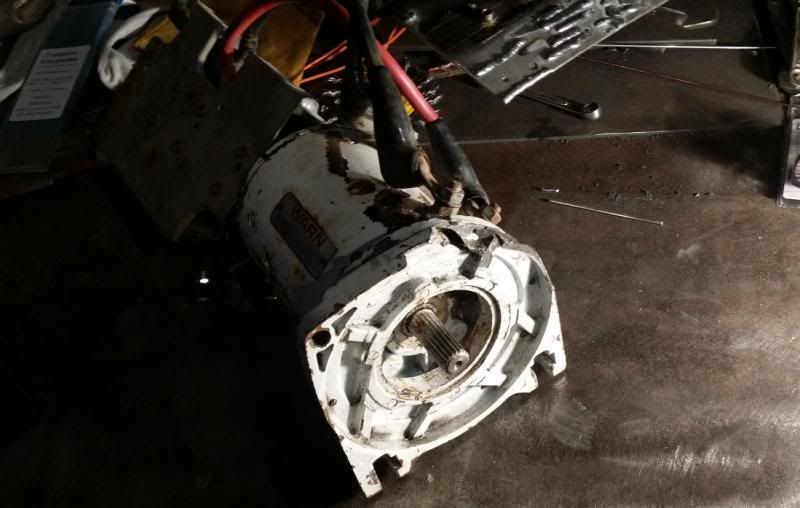

Here's the main problem with the parts pile. The motor mount thingy is busted pretty good on one side. Magnet didn't stick to it, so it's cast aluminum, and not really clean looking aluminum either.

The part is like $80 bucks, and I didn't find any used ones on e-bay or anything. I imagine they get snapped up quick, as it turns out this is a common failure point when the winch is mistreated. So, welding it is.

The most important thing about welding aluminum, especially cast aluminum is cleaning everything up. I probably spent 15 minutes grinding and filing, and it still wasn't enough the first go around. This was my first attempt welding something aluminum that wasn't random scrap.

I had the EP turned up pretty high on the AC balance for the first pass, but you can see the contamination bubbling out of the cast metal. The black stuff is bad.

Gave it several passes without filler with the EP turned up and then cleaned up with a flapper wheel before giving it another go.

Stuff was running better, though I did have to grind a few other spots out to make sure there were no voids or porosity and the main joint.

I've been cleaning everything with a flapper wheel, as it takes stuff off pretty darn quick. However, I'd like something with a little more finesse to get final lines put of everything.

Tried a carbide bit, but it loaded up just like a grinding disc would. Which is unfortunate, thought that would be my final tool.

Anyone do much with aluminum and have any suggestions for a grinding tool? I really don't want to clean this thing up with a file.